How Blockchain Tracks Product Journey in Supply Chains

Feb, 6 2025

Feb, 6 2025

Supply Chain Trace Time Estimator

See how much faster blockchain can trace product journeys compared to traditional systems. Based on real-world examples like Walmart's mango tracing.

How It Works

Traditional supply chains require manual data gathering and communication between parties. Blockchain creates an immutable record that can be accessed instantly. The calculation assumes:

- - Traditional systems take 0.8 hours per step

- - Blockchain systems take 0.05 hours per step

- - Data synchronization adds 2 hours for traditional systems

Trace Time Estimate

Traditional system: -- hours

Blockchain system: -- hours

Time saved: -- hours (--% improvement)

Real-world example: Walmart reduced mango trace time from 7 days to 2.2 seconds using blockchain.

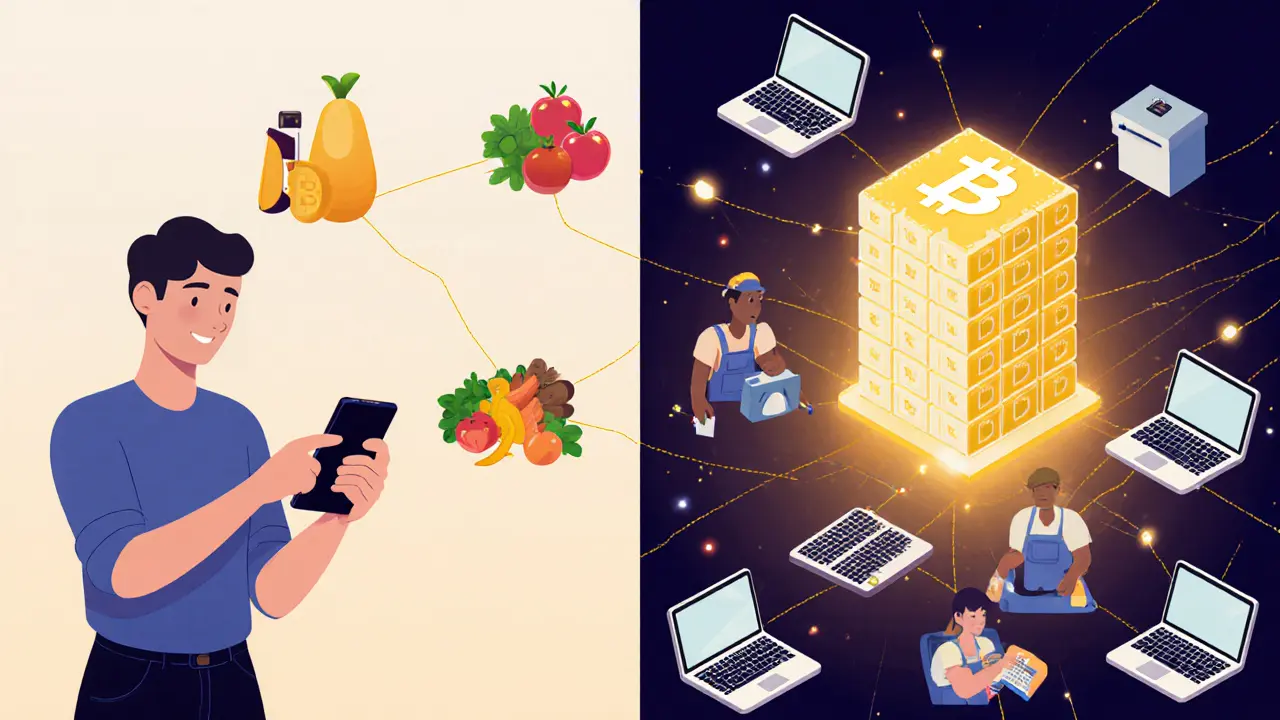

When you buy a carton of milk, a pair of sneakers, or a bottle of medicine, you rarely think about where it came from. But behind that simple purchase is a long, complicated journey-through farms, factories, warehouses, ships, trucks, and stores. And until recently, no one could easily see what happened along the way. That’s where blockchain comes in. It doesn’t just track products. It proves where they’ve been, who touched them, and under what conditions-without anyone being able to lie about it.

How Blockchain Creates an Unbreakable Product Trail

Think of blockchain as a digital notebook that’s copied across hundreds of computers. Every time a product moves-from the farm to the truck, from the port to the warehouse-a new entry is added. That entry includes what happened, when, where, and sometimes even how: temperature readings, humidity levels, GPS location, who signed for it. Once recorded, that entry can’t be changed. Not by accident. Not by mistake. Not on purpose. This isn’t just a fancy database. Traditional systems let one company control the records. If a supplier wants to hide a delay or a spoiled batch, they can edit the file. Blockchain removes that power. No single entity owns the ledger. Instead, multiple trusted parties-farmers, shippers, retailers, regulators-all have a copy. If someone tries to alter a record, every other copy catches the mismatch. The system flags it. The product gets flagged too. For example, in a food supply chain, a mango might be picked in Mexico, packed in a refrigerated container, shipped across the Pacific, cleared through customs, and delivered to a Walmart warehouse. Each step gets logged. If the container’s temperature spiked above 8°C for more than 30 minutes, that’s recorded. If the container was opened without authorization, that’s recorded too. By the time it reaches your local store, you can scan a QR code and see the full history-no guesswork, no paperwork, no hidden gaps.Real-Time Data Meets Immutable Records

Blockchain doesn’t work alone. It teams up with sensors and smart contracts. IoT sensors on pallets, containers, and even individual items send live data: temperature, shock levels, light exposure. That data doesn’t just sit in a spreadsheet. It’s automatically written to the blockchain as a transaction. No manual entry. No human error. Smart contracts are the hidden engines. These are tiny programs stored on the blockchain that run automatically when conditions are met. If a shipment of insulin hits 10°C for more than 15 minutes, the smart contract triggers an alert. It can pause payment to the carrier. It can flag the batch for quarantine. It can notify the pharmacy to hold the order. All without a human needing to open an email or make a call. This isn’t theory. In 2023, a pharmaceutical company using the MediLedger Network saw compliance with U.S. drug safety laws jump from 87% to 99.8%. Why? Because every step-from manufacturer to distributor to pharmacy-was recorded in real time, with no room for falsified paperwork. When regulators asked for proof, they got it instantly.Why Traditional Systems Fail

Before blockchain, tracking a product meant chasing spreadsheets, emails, and phone calls. Walmart used to spend 6 to 7 days tracing the origin of a contaminated mango. That’s not just slow-it’s dangerous. By the time they found the source, dozens of people might have already gotten sick. With IBM Food Trust, that same trace took 2.2 seconds. How? Because every supplier, every warehouse, every trucking company had already logged their part of the journey on the blockchain. No more calling 17 vendors. No more lost invoices. No more “I don’t know who sent that.” The problem with old systems isn’t just speed. It’s trust. In a supply chain with five or six middlemen, who do you believe? The farmer? The shipper? The importer? Each has their own software, their own rules, their own incentives to hide delays or damage. Blockchain removes that chaos by making everyone use the same, unchangeable record.Who’s Using It-and Why

Not every company needs blockchain. If you make chairs in your garage and sell them locally, you don’t need it. But if your product crosses borders, passes through multiple hands, or has strict safety rules, blockchain changes everything. - Food companies use it to prevent contamination and meet FDA and EU regulations. Tracifier’s work with German food suppliers cut processing costs by 40% and boosted data accuracy to 99.9%. - Pharmaceuticals rely on it to fight counterfeit drugs. Everledger’s system reduced fake diamonds in supply chains by 98%. The same tech works for pills, vaccines, and medical devices. - Luxury brands use it to prove authenticity. A $3,000 handbag isn’t just tagged-it’s linked to a digital twin on the blockchain, showing its origin, materials, and every inspection. - Automakers track parts from 500+ suppliers. If a faulty airbag is found, they can instantly pull every affected car without sifting through millions of records. In 2023, 54% of Fortune 500 companies had blockchain in their supply chain plans. The biggest drivers? Regulatory pressure (especially in Europe’s new Digital Product Passport rules), consumer demand for ethical sourcing, and the cost of recalls. A single food recall can cost $10 million. Blockchain makes those rare-and cheaper.The Hidden Costs and Hard Truths

Blockchain isn’t magic. It’s hard work. And it’s expensive. Implementing it can cost between $500,000 and $2 million. That’s not just software. It’s training 75% of your suppliers on new digital tools. It’s rewriting contracts. It’s convincing skeptical partners to share data they’ve guarded for years. Many projects fail because companies try to roll it out everywhere at once. The smart ones start small. They pick one high-risk product-a batch of organic coffee, a line of baby formula-and track just that. If it works, they expand. Another problem? Data standards. If Supplier A logs temperature in Celsius and Supplier B uses Fahrenheit, the system breaks. Successful projects use GS1 global standards to make sure everyone speaks the same language. And then there’s the human factor. On Reddit, logistics professionals complain about “17 different blockchain platforms demanding conflicting data formats.” That’s not blockchain’s fault. It’s poor planning. The best implementations have a dedicated team-people who know supply chains AND blockchain-working side by side with suppliers.

What’s Next for Product Tracking

The next wave isn’t just tracking. It’s predicting. Oracle’s 2024 update added AI that spots patterns before problems happen. If a shipment from a certain port always gets delayed during monsoon season, the system learns that. It flags the route before the delay happens. If a supplier’s temperature logs show a slow drift upward over time, it warns you before the product spoils. Soon, products will have digital twins-exact virtual copies on the blockchain. You won’t just track a bottle of wine. You’ll track its digital twin, which can be sold, traded, or even divided into shares. Imagine owning 10% of a rare vintage barrel, verified on the blockchain. Quantum computing is coming. In 2026, NIST standards will require blockchain systems to use quantum-resistant encryption. Companies that wait will be left behind. The real win? Trust. Not just between companies. Between you and the brand you buy from. When you scan a QR code and see that your coffee beans were picked by farmers paid fairly, grown without pesticides, and shipped in reusable containers-no marketing spin, just proof-that’s powerful.Final Take: It’s Not About the Tech. It’s About the Truth.

Blockchain doesn’t fix broken supply chains. It exposes them. It forces everyone to be honest. It turns guesswork into facts. It turns rumors into records. The technology is mature. The tools exist. The cost is falling. The regulators are watching. And consumers? They’re asking questions. They want to know where their stuff comes from. Not because it’s trendy. Because it matters. If you’re in a complex supply chain-if your product touches more than three countries, more than five suppliers, or more than one set of regulations-blockchain isn’t optional anymore. It’s the only way to prove you’re telling the truth.Can blockchain prevent product counterfeiting?

Yes. Blockchain creates a unique, tamper-proof digital identity for each product. Counterfeiters can copy packaging, but they can’t replicate the blockchain record tied to the real item. Everledger reduced fake diamonds in supply chains by 98% using this method. The same applies to pharmaceuticals, luxury goods, and electronics.

Do I need to change my entire supply chain to use blockchain?

No. The most successful implementations start with a pilot-tracking just one high-value or high-risk product line. Once it works, you expand. Many companies begin with a single supplier or a single product category. Full rollout can take 12-18 months, but value shows in as little as 4-6 months.

How does blockchain improve sustainability reporting?

Blockchain tracks carbon emissions, water use, and ethical labor practices at every stage. Companies can prove Scope 3 emissions (indirect supply chain emissions) with real data, not estimates. The EU’s Corporate Sustainability Reporting Directive (CSRD) now requires this level of detail. Blockchain makes compliance automatic and auditable.

Is blockchain faster than traditional tracking systems?

For tracing origins, yes-dramatically. Walmart reduced mango trace time from 7 days to 2.2 seconds. But for high-frequency updates (like 10,000+ transactions per second), traditional databases like Apache Cassandra still perform better. Blockchain wins on trust and transparency, not raw speed.

What happens if a supplier refuses to join the blockchain network?

They get left out. In industries like food and pharma, major buyers like Walmart or Pfizer now require blockchain participation. Suppliers who don’t join lose contracts. Some companies help by covering the cost of sensors or training. Others offer financial incentives for early adopters. The pressure to join is growing fast.

Can consumers actually access blockchain data?

Yes, through simple tools. QR codes on packaging link to a webpage showing the product’s journey-no tech skills needed. Apps from companies like IBM Food Trust or VeChain let anyone scan and see verified details: origin, handlers, certifications, and even photos from the farm or factory.

Is blockchain secure from hacking?

Enterprise blockchains (like Hyperledger Fabric or Oracle Blockchain Platform) are permissioned, meaning only trusted parties can add data. They’re far more secure than public blockchains like Bitcoin. Tampering requires hacking hundreds of systems at once-practically impossible. The biggest risk isn’t hacking. It’s bad data entry at the source. Garbage in, garbage out.

What industries benefit most from blockchain tracking?

Food and pharmaceuticals lead, due to strict regulations and high risk of contamination or fraud. Luxury goods use it for authenticity. Automotive and electronics track parts across global suppliers. Retailers use it to meet ESG goals and consumer demands. Manufacturing, retail, and life sciences had the highest adoption rates in 2023.

Belle Bormann

November 22, 2025 AT 02:02blockchain for milk? sounds wild but i get it. i scanned a carton of organic milk last week and saw exactly where it was picked, who packed it, and even the temps during shipping. no more guessing if it’s really ‘fresh.’ simple tech, big difference.

Jenny Charland

November 22, 2025 AT 02:56lol so now we’re trusting tech to tell us our food isn’t poisoned? 😏 next they’ll say your toaster is ‘verified’ on blockchain. i’m just waiting for the day a glitch deletes my coffee’s provenance and i have to sue a robot.

stuart white

November 23, 2025 AT 08:39let’s be real - this isn’t innovation, it’s corporate theater. you think Walmart gives a damn about your trust? they care about avoiding $10M recalls. blockchain isn’t truth - it’s liability insurance wrapped in buzzwords. i’ve seen 17 different platforms at one logistics firm. nobody speaks the same language. it’s a mess.

and don’t get me started on ‘smart contracts.’ they’re just glorified if-statements with a fancy name. if temp > 8°C → alert. wow. revolutionary.

the real win? forcing suppliers to digitize. that’s the only thing that’s actually useful here. the rest is just theater.

Lisa Hubbard

November 25, 2025 AT 02:49i read the whole thing. honestly? it’s impressive. but also exhausting. why does every single step of a milk carton’s journey need to be recorded? who has time to scan a qr code before breakfast? i just want my coffee to not be poisoned. i don’t need to know the farmer’s name, the truck’s gps history, or whether the container was opened in port 3.7 seconds after loading.

it’s like they turned a simple thing into a documentary. i’m not watching a Netflix series about my yogurt. i’m eating it. let me enjoy the silence.

also, who pays for all this? the consumer? because if my milk costs $8 now because of blockchain, i’m switching to store brand and pretending i don’t care.

and don’t even get me started on the ‘digital twins’ of wine barrels. are we seriously going to trade fractional ownership of a bottle of chardonnay like it’s crypto? i’m out.

the tech is cool. the application? overkill. the future? exhausting.

Anne Jackson

November 25, 2025 AT 11:51if you’re not using blockchain, you’re letting foreign suppliers lie to you. america used to make things. now we trust some guy in india to log a temperature reading? no thanks. this isn’t just tech - it’s patriotism. if your supply chain can’t prove it’s clean, it shouldn’t be in this country.

the eu’s rules are forcing us to do this. good. we need to stop being soft. if a vaccine comes from a country that doesn’t play by the rules, it shouldn’t be on our shelves. blockchain stops that. period.

preet kaur

November 26, 2025 AT 17:33in india, we’ve been tracking spices for centuries - by hand, by trust, by family reputation. blockchain is new, but the idea? old. what matters is who you believe. if the system makes people honest, great. if it just adds cost and complexity, then we’re missing the point.

the real challenge isn’t tech. it’s teaching small farmers to use apps. not everyone has smartphones. not everyone speaks english. not everyone trusts digital records. we need to build bridges, not just blockchains.

Amanda Cheyne

November 28, 2025 AT 11:04you think this is about truth? think again. blockchain is a government and corporate tool to control what you eat, what you buy, and what you know. every scan is a data point. every qr code is a tracker. they’re building a digital fingerprint on every product you touch - so they can monitor you later.

why do you think they’re pushing this now? because they’re preparing for the next lockdown. when they decide you can’t buy milk unless your phone approves it - you’ll thank them for the blockchain.

the ‘digital twin’? that’s not for you. that’s for the algorithm. they’ll sell your coffee preferences to advertisers. they’ll deny you access to medicine if your ‘supply chain score’ is low.

don’t be fooled. this isn’t transparency. it’s surveillance with a nice interface.

Tyler Boyle

November 30, 2025 AT 07:54you’re all missing the real issue. blockchain isn’t the problem - it’s the data input. if a supplier manually types ‘22°C’ instead of using a sensor, the whole chain is compromised. garbage in, garbage out. the system’s only as good as the dumbest person at the end of the line.

and nobody talks about the energy cost. enterprise blockchains aren’t as bad as Bitcoin, but they’re still running on servers that could power a small town. are we really okay with that for a milk carton?

also, the ‘digital twin’ concept? it’s not science fiction. it’s already being used in aerospace. but applying it to a $2 bottle of aspirin? that’s not innovation - it’s absurd inflation of value.

the real success stories? they’re not in Walmart. they’re in pharma. where a single counterfeit pill can kill someone. that’s where blockchain saves lives. everywhere else? it’s a fancy spreadsheet with extra steps.

and the ‘smart contracts’? they’re just automated penalties. if you’re late, you get fined. if you overheat, you get flagged. that’s not trust - that’s surveillance with a contract.

the hype is real. the impact? selective. the future? still messy.

Sky Sky Report blog

December 2, 2025 AT 04:22the goal of this technology is not to impress or to control but to ensure that when a child receives medicine, it is safe. when a family eats food, it is not contaminated. when a consumer buys a product, they are not deceived. these are not trivial matters. the complexity of modern supply chains demands a solution that is transparent, immutable, and verifiable. the cost and effort are justified by the stakes.

the resistance to change is understandable. but progress often arrives wrapped in unfamiliar tools. the question is not whether blockchain is perfect but whether it is better than what came before. in many cases, the answer is clearly yes.